Product Description

AEM’s Marine-grade Plug & Play Adapter Harness for MEFI-4 equipped race vehicles (PN 30-3829) allows users to switch from the older MEFI-4 platform to state-of-the-art standalone engine control with built-in racing features like boost, nitrous, traction and launch control, in about an hour!

Complete Plug & Play Harness For Mefi-4 Engines

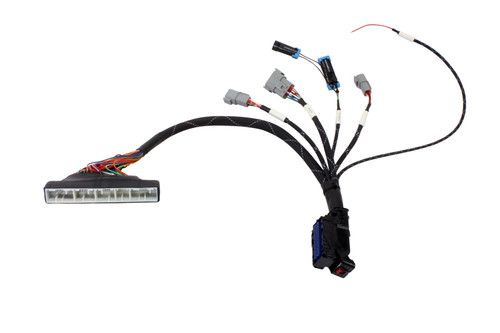

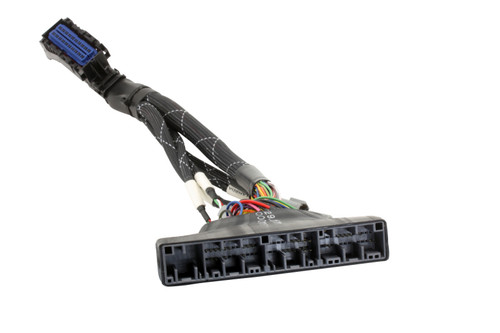

This adapter harness includes MEFI J1 and J2 connectors to attach it to the MEFI harness, a 73 pin Molex connector to attach to an Infinity Series 3 ECU, two Lambda connectors for adding external wideband controllers and sensors, a connector for HEI-distributed engines or the option to run 8 individual AEM smart coils, an AEMnet CAN bus connection for connecting AEMnet enabled devices, an integrated relay and 12-pin DTM style connector for fast and easy integration of auxiliary sensors and switches.

Plug & Play Harness with Expansion Port

An expansion port with a weatherproof 12-pin connector is included in the Plug & Play Adapter Harness for adding common aftermarket sensors including fuel and/or oil pressure (30-2130-150 150 PSI, sold separately) and ethanol content sensor (PN 30-2200 sold separately). The expansion port also includes a sensor ground, 5v reference, power from relay and switched inputs for boost target and more.

Uses Infinity Series 3 Standalone ECU

The Infinity Series 3 Programmable ECU is designed for popular early- and late-model throttle body and port-injected Ford, GM and Mopar V8s.

The Infinity Series 3 incorporates all of the features necessary to run a high-performance engine including airflow-based VE tuning for fuel injection control, ignition control, Flex Fuel, knock control, boost control, nitrous control, launch control, traction control and engine protection. The Series 3 is able to communicate with 3rd party dashes and loggers and is AEMnet CANbus enabled to easily communicate with other AEMnet equipped devices. All maps can be password protected. Its latest generation 200MHz processor can process 400 MIPS (Millions of Instructions per Second).

Air/Fuel Ratio (AFR) feedback is supported by adding external wideband controllers through 0-5V analog inputs or via AEMnet CANbus using AEM’s X-Series Wideband UEGO AFR controllers. An Engine History feature is included that records basic engine operational conditions including Run Time, Peak RPM (overrev), Oil Pressure/Temp Overheat (requires sensors, sold separately) and Lean Condition (Boost/Vacuum vs AFR).