Product Description

The AEM Water/Methanol Injection System Advantage

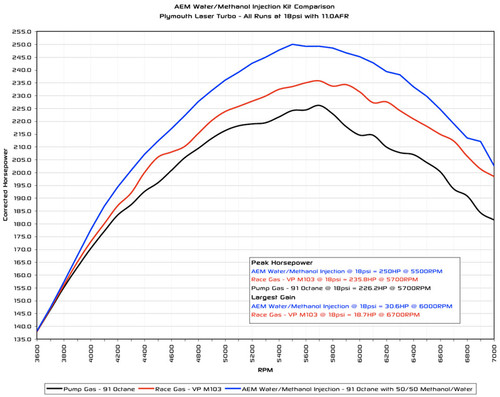

Water/methanol injection for forced induction (turbocharged or supercharged) gas-powered race engines is a proven means for effectively reducing engine inlet air temperatures and suppressing harmful detonation. This allows racers to reliably increase boost and advance ignition timing—without using high-octane racing fuel—for power gains of up to 20%. AEM’s Water/Methanol Injection Systems utilize the most robust hardware combined with more advanced features than any other comparably priced water/methanol system.AEM offers a few different water/methanol controller designs for gas vehicles:

- One is boost dependent for forced induction vehicles up to 35 PSI of boost (kit PN 30-3300). The Boost Dependent controller has an on-board manifold absolute pressure (MAP) sensor with a molded-in nipple for a boost hose pickup.

- The second controller (Kit PN 30-3350) features a multiple input design that enables users to install AEM’s Water/Methanol Injection Kit on ultra-high boost vehicles (above 35 PSI) using a 0-5v voltage-based external MAP sensor.

- The last is a Multi-Input controller and is dependent on an external 0-5v voltage-based external MAP sensor, a frequency based input for Injector Duty Cycle (IDC), frequency-based mass airflow (MAF), or a 0-5v voltage-based MAF.

Key Features :

- Multi-Input (0-5v/frequency) progressive controller design features large adjustment knobs, integrated plug for harness connection, integrated fuse, covered status light and test button for enhanced splash resistance and mounting tabs.

- Wiring harness is terminated with a positive-lock connector on one end with color-coded wires to ease installation, integrated pump ground circuit and additional wire for optional on/off fluid solenoid.

- “Boost Safe” failsafe output included (for complete failsafe under all conditions, see our Water/Methanol Failsafe Device)

- Heavy-duty high-pressure injection pump features integral fittings, a Santoprene diaphragm and EPDM seals to resist corrosion. Our pump maximizes line pressure for optimum atomization and its quiet, smooth operation is almost undetectable

- Precision-machined billet-aluminum injector with integral check valve

- Three interchangeable injector nozzles to cover a wide variety of HP levels (250cc/min, 500 cc/min & 1,000cc/min)

- 1.15 gallon tank with anti-starvation reservoir, integral conductive low-fluid sensor and positive lock connector (tank-less systems available)

- 20 feet of injection tubing included

- LED dash light for system status and low fluid warning

This is for the kit that comes with bare essentials, NO tank or fluid level sensor is included.

This kit can also be used on NA vehicles

Note from AEM : For optimum results, all Water/Methanol Injection Systems and gauges should be run with an AEM inline filter (AEM part # 30-3003)